Shopping cart

Search

Accurl

PRESS BRAKE EASYBEND B SERIES

0.00 AED

• Plate Support Arms • Germany Bosch-Rexroth Hydraulic Germany EMB Tubing connector • Germany Siemens Main Motor • Telemecanique/Schneider Electrics • Hydraulic & Electrical overload protection • Top and Bottom Tooling(86°, R0.6mm) • DELTA Inverter controlled back gauge • Powered Depth Y-axis & Back gauge X-axis • Estun E21 Or Germany ELGO P40 NC contro • HIWIN Ball screws & Polished rod with 0,05 m

CNC PRESS BRAKE EUROPRO B SERIES

0.00 AED

• CNC DELEM DA58T with colour graphics • 4+1-axis CNC: • Y1, Y2 precision ram positioning. •X. R precision servo-driven back gauge. •CNC motorized crowning system •Manually adjustable Z1, Z2-axis. •GIVI optical scales • Lazer Safe dual beam photocells • Voith pump •Hoerbiger hydraulic system •High Siemens efficiency motor-class IE3 •Stand-By and inverter motor drive for energy-saving drive. •Double guided ram • Electrical cabinet with Telemecanique-Schneider, Esautomotion, ABB components Tool kit: 4 V die (V=16-22-35-50) series of 835mm punches with a fractioned one • DSP-AP laser safety lowered speed change point and auto-blanking for box bending

CNC PRESS BRAKE SMART FAB B SERIES

0.00 AED

STANDARD CONFIGURATION • YI/Y2 synchro pressbrake •DELEM DA58T 2D graphical operator control •X-Axis backgaug. prog ammable in 0.1mm increments CNC controlled hydraulic Anti deflection table (crowning) • Programmable, angle, depth and TDC positioning European style quick release clamping for top tools • Full set of top and bottom tooling • 2 Front supports •CE Safety specifications OPTIONS • DELEM DA52s CNC System •DELEM DAB6T CNC Systern •Backgauge X-R or X-R-Z1/Z2 •DSP Optical Safety Guard •1000ram backgauge stroke

PRESS BRAKE SMARTPRO S SERIES

0.00 AED

Maximum productivity thanks to high speed levels Movement of the axis at extremely fast rate Low consumption with inverter Ergonomic design Compact dimensions Work area LED lighting Extremely quiet Possibility to customize tool clampings depending on customer requirements

FIBER LASER WELDING MACHINE

0.00 AED

MODEL : HN-1000H HN-1500H HN-2000H Power: 1000w 1500 W 2000w Wavelength: 1064nm working environment : 10~40°C power supply : 220V/380V 50HZ/60HZ gross weight: 230KGS dimensions(mm): 1200*700*1600mm cooling chiller: industrial water chiller

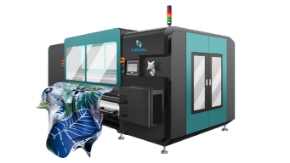

ACCURL FIBER LASER CUTTING MACHINE EASYCUT KJG SERIES

0.00 AED

• Stress relieved laser machine frame • Auto-changing dual pallet system • Light source • Chiller * Radan or Lantek CAD/CAM system • Precision Rack & Pinion Drive System (Made in Germany) • 3 lower protective lenses • 5 Nozzles each ofthe Following: (1.0mm, 1.2mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm) • 3 Ceramic Nozzle Adapters • Auto-calibrated nozzle system • Lens with 5.9" Focus Length • Smart Slag Collection System/ Chip Conveyor • Fiber Beam Transmission System (Fiber Cable) • Operates with both N2 and 02 (cutting) gases • Home Position Alignment System • Auxiliary Gas Selector • Auxiliary Gas Pressure NC function • Auto Reflection Warning • Working Lights • Warning Indicator Lamps • Lens Cleaning Kit • Removal and Adjustment Tools • Ground Plates • User Manuals in English