Shopping cart

Search

Accurl

SECTION BENDING MACHING ARM - ARH - AR4H SERIES

0.00 AED

ARH 50 - 60 • Three rolls are planetaryhydraulic powered • Hardened standardrolls • Digital Read-Out • 2-Axismovablehydrauliclateralguiderollers * 2 Speed working system • Standard 3+3 manual side supports * Special design boxer translatingtype machine, top roll moveable up-down, two bottomrolls moves left-rightaxis AR4H - 60,80,100 • 3 Rolls are motor driven • Toprollhydraulicmoveable up-down • Hardened standardrolls •Horizontal and vertical working position *Brakemotorequippedforthe precision bending

GO GENERAL UNCOILER & STRAIGHTEREN

0.00 AED

• Uncoilder and straightener two in one style improves factory usable space. • Straightening adopts the balance adjusting equipment and suitable for processing higher precision products. • Roller adopts the-solid bearing steel and hard chrome plating treatment.

CNC GANTRY V GROOVER MACHINE VCUT SERIES

0.00 AED

• Grooving machine, a base, a cross beam are used in frame structure design and50mm high strengthlow alloy structural steel workable, using the framework of 20mm Q345 steel plates, the integral rigidity ofthe frame, sturdy and durable. • in strict accordance with the production process of machine tools, the use of electric furnace tempering, the elimination of welding stress reduction equipment deformation. by blasting to ensure the paint coating effect is excellent. • HRL slot machine processing parts using pneumatic clamping system fixed, slotting speed and ensure the strength of the clamping.

CNC Mesh welding Machine

0.00 AED

• Main Body: Adopt the reinforced special design steel structure body with gantry type structure. According to the sample. it is designed cantilever type stucture with arm of 1000mm. It adopts reasonable stress center of gravity to ensure the stable intensity of the main body when conducting fast speed welding. At the meantime, it could provide stress supporting point and working platform for other actions. Power source system: Adopt 1 set of 150KVA special resistance welding transformer as the welding power source. Single-spot welding. Continuous duty cycle rate is 50%; the output current is larger than 38000A. The executive standard is GB/15578-2008; the magnetic permeability of forced temperature control cooling water silicon steel sheet is larger than 12000GS: special cooling water subloop: It can ensure the output welding current of the whole machine is constant and powerful in order to obtain high quality, high efficiency, stable welding spots. Welding Control System: Adopt the self-developed intelligent microcomputer quick response touch controller, all-digital control, simple and clear operational interface. Automatic testing and compensation which could guarantee the situation that the machine will be at work only when the current value is in the preset data so as to ensure the stability of welding effect and effective prevention of undesirable phenomena like loose welding and cold joint. The features of quick response and high precision of control may help you obtain high quality of welding spots. > Pressurized Mechanism: Adopt double-layer cylinder as the pressunzed source which is control by good quality of imported electromagnetic valve and coordinated with procision-machined linear slide to pressure the electrode tip. The pressure of each welding head could be adjusted independently to ensure the stability of welding machine. Adopt the working manner that the bottom bears the stress from the top to guarantee the good contact, unimpeded, constant resistance value of secondary circuit and stable transmission of output current of welding transformer. Guarantee to obtain high efficient and good quality of welding spots. • Main Engine Control System: Adopt the touch sereen as the human-machine interface, Chinese-English input. Be able to store 10 sets of welding model and each model can be stored 500 welding positions and 4 kinds of welding current. The PIC, as the control hub as the whole machine, is in charge of reading. transmitting and controlling all kinds of signal processing and coordinating with various external instructing transmission signal mechanism in order to ensure the validity of all orders of execution of the machine. The self-detection of all automatic testing stations effectively eradicates the occurrence of malfunction and other accidents. When the pressure. current, air pressure, hydraulic pressure, temperature or other testing signals are in abnormal situation, the machine will give an alarm to Prevent any insecure accidents.

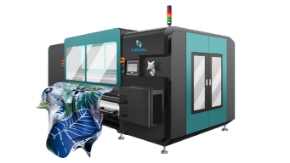

Stainless Steel Sheet Polishing Machine

0.00 AED

Kitchen Equipment Mfg. • Dairies and Breweries Process Machinery Mfg • Pharma & Food Process Machinery Mfg. • Architect and Building construction (A.B.C. Sector) • Lift and elevator manufacturer. • Stainless Steel Tube, Rod and Flat bar user, Mfg. • Automobiles • Railways • Instrumentation