Shopping cart

Search

Accurl

SHEET METAL LASER CUTTING MACHINE

0.00 AED

1. Cast iron machine bed, make sure high precision cutting, and without deformation over 30 years. 2. Cypcut software with essential nesting function, this one allows minimizing waste of raw materials. 3. Raytools autofocus laser head. Automatic height adjustment maintains a constant focal length of the laser while maintaining cut quality stable. 4. Cast aluminum crossbeam provides the laser with high rigidity, stability, and vil ption resistance. 5. The cutting machine has a stable operating system of a high-performance laser Añsuring the best quality cutting. 6. Flawless cooling system, lubrication, and dust removal, so that the laser works stably, reliably

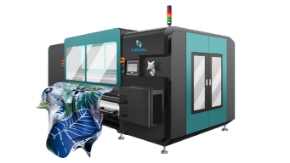

SHEET METAL LASER CUTTING MACHINE

0.00 AED

1. Cast iron machine bed, make sure high precision cutting, and without deformation over 30 years. 2. Cypcut software with essential nesting function, this one allows minimizing waste of raw materials. 3. Raytools autofocus laser head. Automatic height adjustment maintains a constant focal length of the laser while maintaining cut quality stable. 4. Cast aluminum crossbeam provides the laser with high rigidity, stability, and vibration resistance. 5. The cutting machine has a stable operating system of a high-performance laser, ensuring the best quality cutting. 6. Flawless cooling system, lubrication, and dust removal, so that the laser works stably, reliably, and efficiently

SWING BEAM SHEARS EASYCUT S SERIES

0.00 AED

- Rapid and precise blade clearance adjustment with a single handle on the side frame * Multi-edge blades for cutting aluminum, carbon steel, and stainless steel • Cutting-line illumination and wire for shadow-line cutting • Stroke counter • Quick cutting-length adjustment • Hydraulic and electrical overload protection • Squaring arm and front support arms • Bed infill plates with ball transfers • Delta inverter with ball screw and polished rod with 0.01 mm accuracy • Backgauge adjustment according to blade gap • Backgauge retraction feature • Sub-program and programming loop • Sequence repeat function * Auto-cutting (Flying cut)

HYDRAULIC 4-ROLLER PLATE BENDING MACHINE

0.00 AED

• Cone Bending device • Induction hardened rolls • Digital display for both side rollers • Machine body is steel (ST-52) construction • Seperate control panel - Two speed control - All rollers mounted in bearing Drop Led controlled from control panel in order to release easily bent metal sheetand lifted upper rolls • Cone open and close controlled from panel - Center rolls are driven with hydraulic motorand planetry gear box • Suitable for CE, ISO 9001-2008, TSK and TURQUM certificates

MECHANICAL 3-ROLLER ROLLING MACHINE

0.00 AED

Its upper roller can lift and two bottom rollers can move horizontally separately or synchronously. Every bottom roller-perform functions of bottom roller and sider roller in turn, become two types non-symmetrical three roller rolling plate machine, which can fish pre-bend and roll of thin and thick plate at the same time. It is convenient to roll taper work piece. Note: The machine that more than25*2500 adopts discharge by hydraulic connection plate.

3 ROLLS ASYMETRICAL PLATE BENDING MACHINES W11F SERIES

0.00 AED

• Induction hardened rolls. • Backroll with motor. • Cone bending device. • Body steel (St-52) construction. • Rolls are produced by special steel. • Machine designed in asymetrical working principle. • Central rollers powered with electric motor + gearbox and gear system. • Upper roll is opanable by side. • Seperate control panel. • Suitable for CE, ISO 9001-2008, TSK and TURQUM certificates