Shopping cart

Search

SABAZU

| Attribute | Details |

|---|---|

| Founded | 1996 in India. (sabazu.com) |

| Management | Run by professionally qualified engineers. (sabazu.com) |

| Geographic Presence | India (Headquartered in Kodungallur, Thrissur, Kerala), Oman (since ~1999), UAE (since ~2008), also operations in Bahrain. Qatar presence coming soon. (sabazu.com) |

| Main Products / Business Lines | |

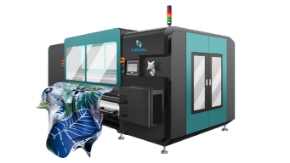

| • UV flatbed printers, UV roll-to-roll, hybrid UV printers (TradeIndia) | |

| • 3D printers (sabazu.com) | |

| • CNC machines (routers, etc.) (TradeIndia) | |

| • Laser engraving & cutting machines, plasma cutters (sabazu.com) | |

| • Industrial automation controls, industrial X-ray equipment, advertisement media equipment & security camera systems. (sabazu.com) | |

| Other Products | |

| Scale | |

| • Employee size: ~110 (per some directories) in India. (TradeIndia) | |

| • Annual turnover: ~ USD 12 million in some reports. (TradeIndia) | |

| Contact Details | |

| • India – Kodungallur, Thrissur, Kerala. (TradeIndia) | |

| • Oman – & UAE, Bahrain offices. (sabazu.com) | |

| Quality / Features | They emphasize total quality management, precision, customization, defect-free supply, dimensional accuracy. (sabazu.com) |

Featured products

Spot Welding Machine

The medium frequency inverter spot weiding machine can rectify three-phase AC to DC and DC inverters into medium frequency 1000Hz square wave through the inverter circuit oomposed of IGBT. Then medium frequency 1000Hz square wave is connected into the primary of welding transformer, and the welding transformer make it with lower voltage and rectify it to be a dc supply electrode with little pulsation to the electrodes lo weld the work piece. The inverter can adjust the duty ratio of IGBT by feedback the primary or secondary welding current, so as to achieve the efect of constant current in the welding process.

CNC Router

H1WIN guiderail Art cam software Oil misting Working voltage for single phase 220v

SH 3015 C Sheet and Tube Combo C Series

Open Type Sheet and Tube Combo C Series Sabazu Open-Type “C” Combo, engineered for start-ups, brings you dual sheet & tube cutting in one compact platform — from 1.5 kW up to 6 kW, handling sheets up to 6050 × 2030 mm and tubes 20-220 mm, with a 2000 kg load capacity — all backed by CE & FDA certifications. Alternate versions / tag-lines you might like: “Sabazu C-Series Combo: power and versatility in one compact platform — sheet and tube, certified and startup-friendly.” “Your startup’s cutting edge: Sabazu C Combo — dual sheet & tube, 1.5–6 kW, certified, compact, and cost-smart.” “Sabazu’s Open Type C Combo: small footprint, big performance — sheet/tube cutting made affordable and certified.” 1.5-6 [kW] Laser power 3050*1530-6050*2030 [mm] Sheet size 20~220 [mm] Scope of tube size 2800 [kg] Max load of sheet platform

SH 3015 LASER CUTTING MACHINE

Sabazu SH3015 Laser Cutting Machine (N-Series) is a technically enhanced yet cost-effective ,engineered for medium-thin metal sheets (up to approximately 20 mm). It features a high-strength semi-hollow machine bed and a high-strength aluminum-alloy beam for rigidity with reduced mass. Equipped with a fully automatic focus mechanism and an intelligent following system, it ensures excellent cut quality even on mildly uneven surfaces. The machine is available in laser powers from 1.5 to 6 kW, supports sheet sizes ranging from 3050×1530 mm to 6050×2030 mm, achieves no-load traverse speeds of up to 100 m/min, and offers a work‐platform load capacity between 700-2000 kg. Its open-style structure and compact footprint make it especially attractive for workshops with limited plant area.

SH 6015 LASER CUTTING MACHINE

The Sabazu SH3015 Laser Cutting Machine (N-Series) is a technically enhanced yet cost-effective 2024 model engineered for medium-thin metal sheets (up to approximately 20 mm). It features a high-strength semi-hollow machine bed and a high-strength aluminum-alloy beam for rigidity with reduced mass. Equipped with a fully automatic focus mechanism and an intelligent following system, it ensures excellent cut quality even on mildly uneven surfaces. The machine is available in laser powers from 1.5 to 6 kW, supports sheet sizes ranging from 3050×1530 mm to 6050×2030 mm, achieves no-load traverse speeds of up to 100 m/min, and offers a work‐platform load capacity between 700-2000 kg. Its open-style structure and compact footprint make it especially attractive for workshops with limited plant area.

SH 3015 NP LASER CUTTING MACHINE

The Sabazu SH3015 Laser Cutting Machine (N-Series) is a technically enhanced yet cost-effective 2024 model engineered for medium-thin metal sheets (up to approximately 20 mm). It features a high-strength semi-hollow machine bed and a high-strength aluminum-alloy beam for rigidity with reduced mass. Equipped with a fully automatic focus mechanism and an intelligent following system, it ensures excellent cut quality even on mildly uneven surfaces. The machine is available in laser powers from 1.5 to 6 kW, supports sheet sizes ranging from 3050×1530 mm to 6050×2030 mm, achieves no-load traverse speeds of up to 100 m/min, and offers a work‐platform load capacity between 700-2000 kg. Its open-style structure and compact footprint make it especially attractive for workshops with limited plant area. SH 3015NP LASER SOURCE 1 MAX LASER CUTTING HEAD 1 RAYTOOLS TRANSMISSION SYSTEM 4 AIRTAC TAIWAN MACHINE TOOL AND ACCESSORY 1 AIRTAC TAIWAN REDUCER 3 JAPAN SHIMPO ELETRICAL AND PNEUMATIC SYSTEMS 1 SCHNEIDER , FRANCE AVENTICS ,GERMANY AC SERVO MOTOR AND DRIVER 4 FUJI JAPAN WATER COOLER 1 TONGFEI CNC LASER CUTTING SYSTEM 1 FSCUT 3-12 [kW] Laser power 3050*1530-6050*2030[mm] Sheet size 120 [m/min] Maximum no-load speed 2800[kg] Maximum Load

SH 3015 HC LASER CUTTING MACHINE

The Sabazu SH3015 Laser Cutting Machine (N-Series) is a technically enhanced yet cost-effective 2024 model engineered for medium-thin metal sheets (up to approximately 20 mm). It features a high-strength semi-hollow machine bed and a high-strength aluminum-alloy beam for rigidity with reduced mass. Equipped with a fully automatic focus mechanism and an intelligent following system, it ensures excellent cut quality even on mildly uneven surfaces. The machine is available in laser powers from 1.5 to 6 kW, supports sheet sizes ranging from 3050×1530 mm to 6050×2030 mm, achieves no-load traverse speeds of up to 100 m/min, and offers a work‐platform load capacity between 700-2000 kg. Its open-style structure and compact footprint make it especially attractive for workshops with limited plant area. 1.5-12 [kW] Laser power 3050*1530 [mm] Max sheet size 130 [m/min] Max no-load speed 1100 [kg] Max load of platforms

Full Cover Sheet & Tube Laser Cutter-HM SABAZU Series

HM SABAZU Series — Full Cover Sheet & Tube Laser Cutter The HM SABAZU Series is a high-efficiency, dual-purpose laser cutting machine capable of cutting both sheet metal and tubes with precision and reliability. Designed to deliver exceptional value, this machine significantly reduces initial purchase costs—at least 50% lower than conventional alternatives—while maximizing workspace efficiency thanks to its compact footprint (up to 50% smaller than typical models). Built for performance and compliance, the HM SABAZU Series carries multiple international certifications including CE-TUV, FDA, RoHS, and ETL, assuring quality, safety, and global standards. Key Features & Benefits Dual Cutting Capability: One machine handles both sheet metal and tube cutting, making it a versatile solution for diverse fabrication needs. Cost-Effective Investment: Lower purchase and operating costs help businesses—especially startups and small workshops—boost productivity without large capital outlay. Space-Saving Design: Compact footprint allows better utilization of workshop space, freeing up room for other equipment or operations. Certified Quality: International compliance with CE-TUV, FDA, RoHS, and ETL certifications ensures reliability, safety, and adherence to global standards. Technical Specifications Laser Power: 1.5 – 6 kW Sheet Cutting Area: 3050 × 1530 mm to 6050 × 2030 mm Scope of Tube Size: 20 – 220 mm diameter Maximum Load of Sheet Platform: 2000 kg

Sheet Bending Machine-SBDE 17042

CNC system - delem da53t Hydraulic control system-rexroth Oil pump-hytek Main motor-INOVANCE Magnetic-scale Transmission part-HIWIN Cylinder seal original- SKF Main eletrical parts-SCHNEIDER Compression fittings-EMB Deflection compensation-Huangshi Laser protection-LNTECH

Tube Laser Cutting Machine — T Series

Tube Laser Cutting Machine — T Series The SABAZU T Series tube laser cutting machine is designed for high-precision, high-efficiency tube processing across a wide range of material types and sizes. Built with robust engineering and advanced laser technology, this system delivers ultra-short tailing, fast cutting speeds, and reliable performance for demanding industrial applications.

FIBER LASER WELDING MACHINE 2KW

Sabazu’s hand-held fiber laser welding machine uses the latest generation of fiber laser generators. It fills the gap in the welding industry by offering portability and high performance in hand-held welding. Designed for simplicity, quality, and speed, the machine brings together modern laser technology with ease of use.

FIBER LASER WELDING MACHINE 3 KW-SN 3000

Water coolde fiber laser Welding machine

Pulse Laser Welding Machine – 450 W

SABAZU Pulse Laser Welding Machine – 450 W Laser Power & Performance The 450 W laser delivers excellent performance for thin-gauge precision welding, making it ideal for welding small stainless steel components, fine joints, and detailed metalwork. The machine reliably handles a welding thickness range of 0.1 mm to 1.2 mm, perfect for delicate sheet applications and high-precision fabrication.

Robot-Integrated Fiber Laser Cutting System-SH RC 2000-6000

A high-performance robotic fiber laser cutting solution built on a robust gantry frame. Designed for precision cutting of sheet and profile materials in industrial fabrication environments — combining flexibility, power, and automation.

Sheet bending machine SBDE 25032

SABAZU Electro-Hydraulic Hybrid Press Brake The SABAZU Electro-Hydraulic Hybrid Press Brake is a high-precision metal bending machine that combines advanced CNC control with a robust electro-hydraulic drive system. Designed for accurate, repeatable bending operations, this press brake is ideal for a wide range of sheet metal fabrication applications.