(0) items

You have no items in your shopping cart.

All Categories

Menu

Shopping cart

Filters

Personal menu

Preferences

Search

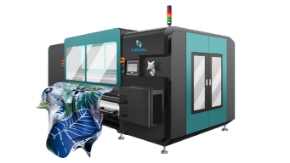

Products tagged with 'cutting machine'

cutting machine

Manufacturers

Customer service

My account

Contact Us

- UAE, Bahrain, Oman, India

- info@sabazu.com

- +971 557486996, +971 505190710, +96898472757, +97332148747, +918589840285