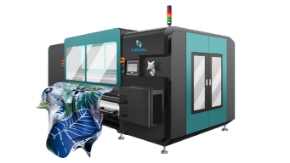

CUTTING HEAD

• The laser beam is delivered to the cutting head by fiber optic cable.

• The fiber optic cable is fixed to the input of cutting head.

• The laser is delivered to the focusing unit after being aligned in the collimator.

• The laser beam is set to desired focus using the lenses in the focusing unit.

• The protection glass protects the lenses from the particles which are caused by the cutting operation.

• The sensor insert is part of the elevation control system and helps to adjust the distance between material and cuttinghead.

• Elevation control is checked with the most precise sensors in the market. This helps to produce better cuts.

• The main function of the ceramic is to protect the cutting head.

• The nozzle is used to control the assist gases. It is also a part of the cap

OPTIONAL COMPONENTS

• Linear Drive

• Dust Collection Unit • Additional Operator Glasses

• Lens with 7.874” Focus Length

• Sheet loading & unloading systems

• Automation & Storage systems

• Automatic Nozzle Changer

• Custom table sizes

• Up to 6 kW laser laser light sources

• Light safety barrier

• Air conditioner for electrical panel

• Metalix, Almacam etc. CAD/CAM software

• LCM (laser cut monitor) sensor for pierce detection

and cut